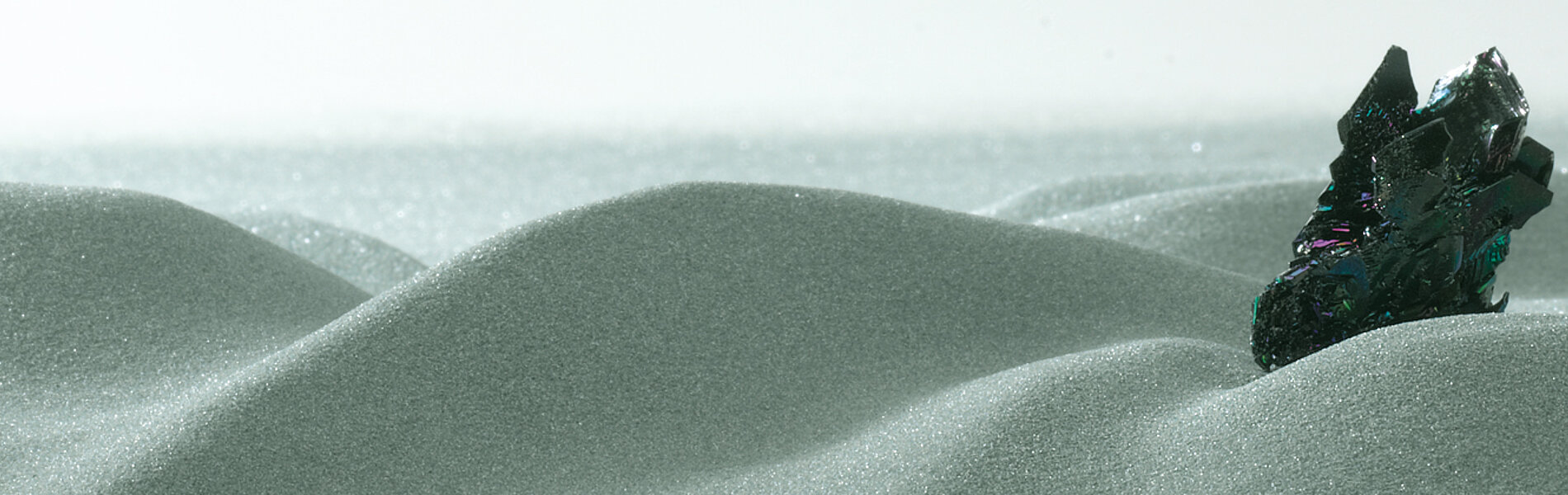

Silicon carbide production process

Silicon carbide (SiC) is most commonly produced in electrical resistance furnaces. A mixture of carbon material (usually petroleum coke) and silica or quartz sand is reacted chemically at high temperatures in the range of 1700 – 2500°C.

After a cooling period, the SiC ingot is sorted accurately and further processed. The SiC crude material is carefully crushed, classified, sometimes milled again, and optionally, chemically treated to enhance its purity and achieve essential characteristics.

One-to-many production

"No material is getting wasted" describes the SiC synthesis appropriately. Material with lower purity from the Acheson furnace is simply recycled into the next furnace runs.

Understanding our customer expectations combined with Fiven's unique production capabilities and knowledge helped to achieve 100% usage of all material produced.

To meet international standards, all Fiven plants operate under ISO 14.001. This enables the organization to improve its environmental performance, meet legal and other obligations, and achieve ecological goals.

Fiven has committed to reducing waste and emissions by eliminating, capturing, cleaning, or recycling it. Our goal is net-zero emissions by 2050. Please find out more on our Environmental Roadmap.