SIKA® ABR

Silicon Carbide for abrasive applications

SIKA® ABR

Silicon Carbide for Abrasives

Silicon carbide is a ceramic material with an excellent hardness, which is only surpassed by diamond, cubic boron nitride and boron carbide.

Due to its high abrasion resistance and relatively low cost, silicon carbide is used as a loose or fixed abrasive material in a variety of applications.

These hard and brittle abrasive grains, which tend to disintegrate under pressure, make SiC articles sharper, cut faster and produce finer scratch patterns on most surfaces.

Silicon carbide grinding tools are widely used for grinding steel, cast iron, carbide, aluminum & non-ferrous metals, plastics & rubber.

Fiven offers a full range of macro and micro grains in black and green quality as well as various particle size distributions based on FEPA, ANSI, JIS and CAMI standards.

A range of grades is available reflecting different surface treatments from air and water dedusting to chemical surface treatment.

In addition to these products, Fiven also offers tailor-made products to order.

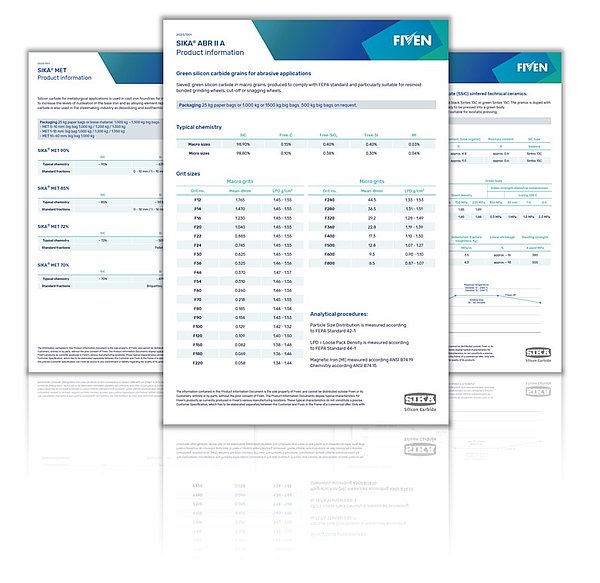

Documents

Download

SIKA ABR I - Chemically treated, high purity green silicon carbide in macro and micro grains

SIKA ABR II A - Air dedusted, green silicon carbide in macro grains

SIKA ABR II - Water washed, high purity green silicon carbide in macro and micro grains

SIKA ABR III - Chemically treated, high purity black silicon carbide in macro and micro grain

SIKA ABR III L - Black silicon carbide grains for lapping applications

SIKA ABR IV - Water-washed, high purity black silicon carbide in macro grains

SIKA ABR IV A - Black silicon carbide grains for abrasive applications

SIKA ABR JIS - Chemically treated, high purity green silicon carbide in micro grains

SIKA ABR P - High quality black silicon carbide in macro and micro grains