Silicon carbide for the steel industry

Silicon carbide is used as an energy booster in steel converters.

Silicon carbide is an effective material when used as a thermal input in LD/BOF converters. The combination of silicon and carbon in silicon carbide creates an exothermic reaction that releases energy into the process (as shown in equations 1 and 2). This exothermic reaction also results in a slag with a less acidic chemical composition, compared to the slag produced by other alloys. As a result, the process using silicon carbide requires less lime compared to processes using other exothermic agents.

Equation 1 <Si> + (O2) = <SiO2> ΔH =- 901,76KJ/Mol

Equation 2 <C> + (O2)= (CO2) ΔH = -393,04KJ/Mol

SiC is used as thermal input in the following situations:

- Pig iron with low initial temperature

- Pig iron with low content of silicon

- High scrap content in the BOF converter

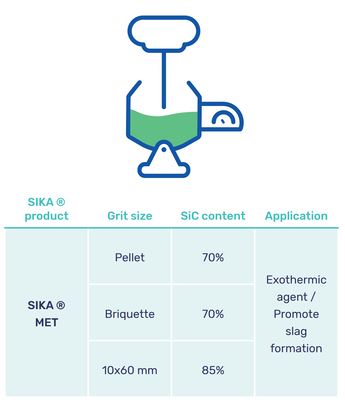

SIKA® silicon carbide for the use in steel production

LD/BOF

Silicon carbide is a powerful fuel for BOF steel-making because of providing energy to the process. By adding silicon carbide, steel-making can raise the temperature within the LD furnace and increase the usage of scrap being more cost-effective. The exothermic property of silicon carbide is more cost-effective compared with ferrosilicon; in addition silicon carbide has lower impurities than Sulfur and Aluminum.

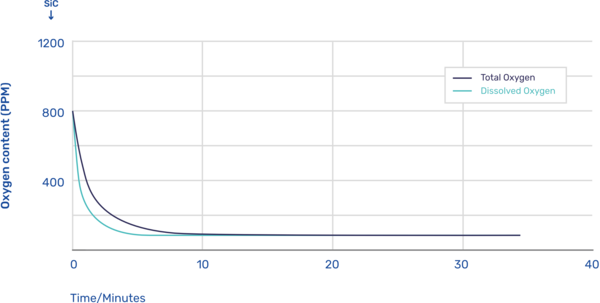

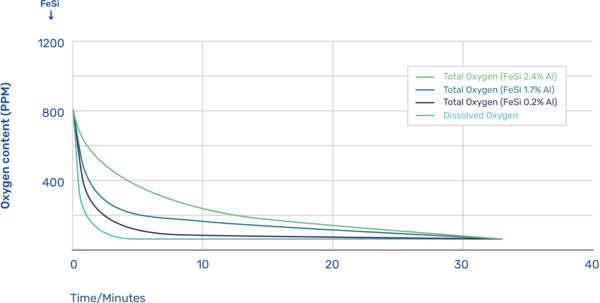

Ladle furnace

Silicon carbide functions as a good deoxidizing agent during the transfer of the liquid metal from the electric furnace to the ladle. The deoxidation kinetics is similar to ferrosilicon alloys. However, silicon carbide presents lower levels of impurity (aluminum) than FeSi. In this way, the possibility of inclusions (Al₂O₃) in the material obtained by the process that uses silicon carbide is smaller compared to the use of ferrosilicon, which guarantees a higher quality of the final product.

- Quick deoxidation of the bath

- Less probability of forming inclusions in the final product

Advantages of silicon carbide in steel mills

Low content of impurities

Aluminium, nitrogen and hydrogen are elements that excess can cause defects such as porosity or inclusions in steel. Silicon carbide is naturally low in these impurities when compared to other sources of silicon and carbon which makes it possible to produce steels with greater limpidity.

Cost reduction BOF Furnaces

By incorporating silicon carbide in the Basic Oxygen Furnace (BOF) furnace, steel manufacturers can significantly enhance their operational efficiency. The inclusion of silicon carbide allows for higher temperatures to be reached within the furnace, thereby enabling the utilization of a greater amount of scrap metal while maintaining cost-effectiveness. Moreover, the incorporation of silicon carbide brings about a reduction in lime consumption, further improving the overall efficiency of the steelmaking process.

Cost reduction Ladle Furnaces

Since silicon carbide simultaneously provides silicon and carbon in steel, two raw materials, one as a source of silicon and one as a source of carbon, can be replaced by silicon carbide. This leads to a cost reduction in the during the process of adding alloying elements. In addition, silicon carbide can be used during the transfer from the electric furnace to the ladle furnace to deoxidize the steel without any risk of operational problems.

Learn about Fiven's silicon carbide products for steel mills