Carburo de silicio para la industria siderúrgica

El carburo de silicio se utiliza como refuerzo energético en los convertidores de acero.

El carburo de silicio es un material eficaz cuando se utiliza como aporte térmico en los convertidores LD/BOF. La combinación de silicio y carbono en el carburo de silicio crea una reacción exotérmica que libera energía en el proceso (como se muestra en las ecuaciones 1 y 2). Esta reacción exotérmica también da lugar a una escoria con una composición química menos ácida, en comparación con la escoria producida por otras aleaciones. Como resultado, el proceso que utiliza carburo de silicio requiere menos cal en comparación con los procesos que utilizan otros agentes exotérmicos.

Ecuación 1 <Si> + (O2) = <SiO2> ΔH =- 901,76KJ/Mol

Ecuación 2 <C> + (O2)= (CO2) ΔH = -393,04KJ/Mol

El SiC se utiliza como aporte térmico en las siguientes situaciones:

- Fundición en bruto con baja temperatura inicial

- Arrabio con bajo contenido de silicio

- Alto contenido de chatarra en el convertidor BOF

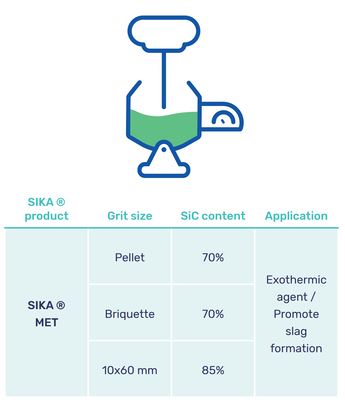

Carburo de silicio SIKA® para la producción de acero

LD/BOF

Silicon carbide is a powerful fuel for BOF steel-making because of providing energy to the process. By adding silicon carbide, steel-making can raise the temperature within the LD furnace and increase the usage of scrap being more cost-effective. The exothermic property of silicon carbide is more cost-effective compared with ferrosilicon; in addition silicon carbide has lower impurities than Sulfur and Aluminum.

Ladle furnace

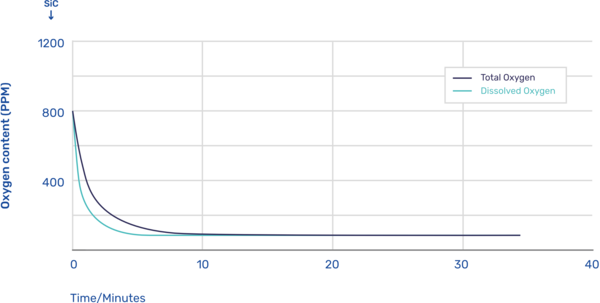

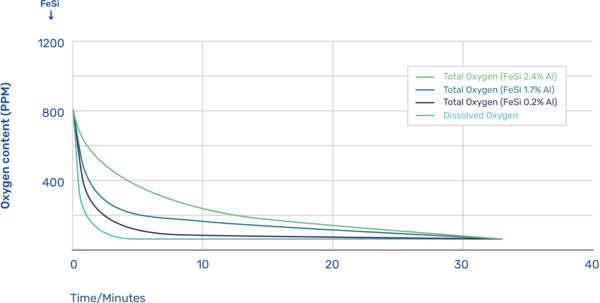

Silicon carbide functions as a good deoxidizing agent during the transfer of the liquid metal from the electric furnace to the ladle. The deoxidation kinetics is similar to ferrosilicon alloys. However, silicon carbide presents lower levels of impurity (aluminum) than FeSi. In this way, the possibility of inclusions (Al₂O₃) in the material obtained by the process that uses silicon carbide is smaller compared to the use of ferrosilicon, which guarantees a higher quality of the final product.

- Quick deoxidation of the bath

- Less probability of forming inclusions in the final product

Ventajas del carburo de silicio en las acerías

Low content of impurities

Aluminium, nitrogen and hydrogen are elements that excess can cause defects such as porosity or inclusions in steel. Silicon carbide is naturally low in these impurities when compared to other sources of silicon and carbon which makes it possible to produce steels with greater limpidity.

Cost reduction BOF Furnaces

By incorporating silicon carbide in the Basic Oxygen Furnace (BOF) furnace, steel manufacturers can significantly enhance their operational efficiency. The inclusion of silicon carbide allows for higher temperatures to be reached within the furnace, thereby enabling the utilization of a greater amount of scrap metal while maintaining cost-effectiveness. Moreover, the incorporation of silicon carbide brings about a reduction in lime consumption, further improving the overall efficiency of the steelmaking process.

Cost reduction Ladle Furnaces

Since silicon carbide simultaneously provides silicon and carbon in steel, two raw materials, one as a source of silicon and one as a source of carbon, can be replaced by silicon carbide. This leads to a cost reduction in the during the process of adding alloying elements. In addition, silicon carbide can be used during the transfer from the electric furnace to the ladle furnace to deoxidize the steel without any risk of operational problems.

Conozca los productos de carburo de silicio de Fiven para acerías